Magna-Mike 8600

The Magna-Mike® 8600 is a portable thickness gauge that uses a simple magnetic method to make reliable and repeatable measurements on nonferrous materials. Operation of the Magna-Mike is very simple. Measurements are made when its magnetic probe is held or scanned on one side of the test material and a small target ball (or disk or wire) is placed on the opposite side or dropped inside a container. The probe’s Hall Effect sensor measures the distance between the probe tip and target ball. The measurements are instantly displayed on the large color thickness display as an easy-to-read digital thickness reading.

New Features

|

|

Three New Probe Designs

The Magna-Mike is available with straight, right angle, and low-profile articulating magnetic probes. The 86PR-1 and 86PR-2 feature replacable wear cap to extend the probe’s durability and reduce replacement costs.

|

Removable Standard Wear Cap 86PR1-WC |

Removable Extended Wear Cap 86PR1-EWC |

Removable Chisel Tip Wear Cap 86PR1-CWC |

86PR-3 Low-profile Articulating Probe |

Measures from 0.001 mm (0.0001 in.) to 25.4mm (1 in.)

The Magna-Mike offers an expanded list of target options greatly extend its measurement capability.

| Targets | Min Thickness | Max Thickness | Accuracy | |

| Basic Calibration | Multipoint | |||

| 86PR-1 and 86PR-2 | ||||

| 1/16 in. (1.58 mm) ball (80TB1) | 0.0001 in. (0.001 mm) | 0.080 in. (2.03 mm) | 4% | 3% |

| 1/8 in. (3.17 mm) ball (80TB2) | 0.0001 in. (0.001 mm) | 0.240 in. (6.1 mm) | 4% | 2% |

| 3/16 in. (4.76 mm) ball (80TB3) | 0.0001 in. (0.001 mm) | 0.360 in. (9.1 mm) | 3% | 1% |

| 1/4 in. (6.35 mm) ball (80TB4) | 0.0001 in. (0.001 mm) | 0.360 in. (9.1 mm) | 3% | 1% |

| 3/16 in. (4.76 mm) magnetic ball (86TBM3) | 0.160 in. (4.06 mm) | 0.750 in. (19.05 mm) | 3% | 1% |

| 1/4 in. (6.35 mm) magnetic ball (86TBM4) | 0.160 in. (4.06 mm) | 1.00 in. (25.4 mm) | 3% | 1% |

| 0.500 in. (12.7 mm) flat disk (80TD1) | 0.0001 in. (0.001 mm) | 0.360 in. (9.1 mm) | 3% | 2% |

| 0.250 in. (6.35 mm) V-edge disk (80TD2) | 0.0001 in. (0.001 mm) | 0.240 in. (6.0 mm) | 3% | 2% |

| 0.045 in. (1.14 mm) dia. wire (86TW1) | 0.0001 in. (0.001 mm) | 0.500 in. (12.7 mm) | 3% | 2% |

| 0.026 in. (0.66 mm) dia. wire (86TW2) | 0.0001 in. (0.001 mm) | 0.240 in. (6.1 mm) | ||

| New 86PR-3 Low-profile Articulating Probe | ||||

| 1/16 in. (1.58 mm) ball (80TB1) | 0.0001 in. (0.001 mm) | 0.080 in. (2.0 mm) | 4% | 3% |

| 1/8 in. (3.17 mm) ball (80TB2) | 0.0001 in. (0.001 mm) | 0.160 in. (4.1 mm) | 4% | 2% |

| 0.026 in. (0.66 mm) dia. wire (86TW2) | 0.0001 in. (0.001 mm) | 0.160 in. (4.1 mm) | 3% | 2% |

Note: For 86PR-1 and 86PR-2 probes the Measurement Tolerance = [(accuracy x thickness) +0.0001 in. or 0.003 mm)], for 86PR-3 the Measurement Tolerance = [(accuracy x thickness) + (0.001 in. or 0.025 mm)]

Internal Alphanumeric Data Logger

The Magna-Mike® has an extensive file-based alphanumeric data logger that is designed to easily store and transfer thickness readings.

You have the ability to store thickness readings in one of four standard file formats: Incremental, Sequential, Sequential with Custom Point and 2-D Grid.

- Single Send or File Send directly to an Excel spread sheet using WINXL

- Send data to other SPC program

- Both USB and RS-232 outputs

- Export files to a removable MicroSD card in .txt and CSV formats

- Generate on-board reports

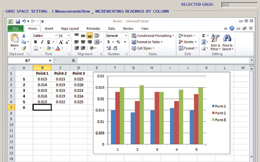

Direct Interface to Excel Spread SheetsThe Magna-Mike 8600 has RS-232 and USB outputs that enable the instrument to directly send data to an Excel spread sheet. The included WINXL interface program enables you to single send or file send thickness readings. |

WINXL interface program |

Reviews

There are no reviews yet.