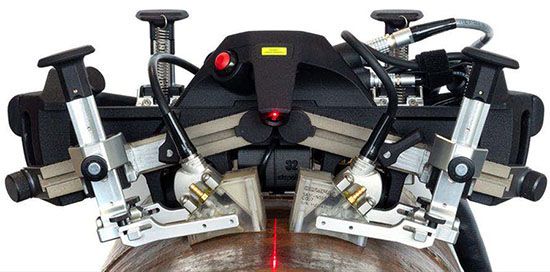

AxSEAM Semiautomated Scanner for Longitudinal Seam Weld InspectionOptimized for long seam weld inspection, such as in electric resistance welded (ERW) pipes, the AxSEAM™ scanner’s simple design minimizes the number of adjustments required when changing pipe diameters, probe separation, or scan orientation. An operator can set up and perform the scan independently without needing to manipulate or monitor the data acquisition instrument thanks to the innovative ScanDeck™ module. The redesigned, easily adjustable probe holders support up to four phased array (PA) and time-of-flight diffraction (TOFD) probes. |

Versatile Multitechnology SolutionWhen used with the OmniScan™ X3 flaw detector, the AxSEAM scanner enables fast PA/TOFD screening of long seam welds followed by more targeted inspection of regions of interest using the total focusing method (TFM)—without needing to switch the probes. TFM provides even focus in the region of interest, making it easier to characterize the difficult-to-detect indications that are typical in ERW long seams, such as vertical flaws and hook cracks. |

|

|---|

Flexible ConfigurationThe AxSEAM scanner offers a complete scanning system, requiring only minor adjustments to switch between longitudinal and circumferential scanning on pipes. |

||

Longitudinal

|

Circumferential

|

|

AxSEAM scanner can scan longitudinal welds on pipes from 152.4 mm (6 in.) OD up to flat

AxSEAM scanner can scan longitudinal welds on pipes from 152.4 mm (6 in.) OD up to flat With 2 probes, the AxSEAM scanner can inspect circumferential welds on pipes as small as 114 mm (4.5 in.) OD

With 2 probes, the AxSEAM scanner can inspect circumferential welds on pipes as small as 114 mm (4.5 in.) OD probes, it can scan circumferentially on pipes starting at 254 mm (10 in.) OD [a 324 mm (12.75 in.) OD pipe is shown above]

probes, it can scan circumferentially on pipes starting at 254 mm (10 in.) OD [a 324 mm (12.75 in.) OD pipe is shown above]

Reviews

There are no reviews yet.